Dust pollution is a major environmental problem and the main cause of occupational health hazards (Surui X., 2020). Some works prove that rail transportation of coal has a certain effect on heavy metals in street dust (source). Other studies showed the effects of different concentrations of PM2.5 exposure on the cardiopulmonary function of manganese mine workers (source). The results showed that PM2.5 exposure caused damage to the lung function of open-pit manganese mine workers, and restrictive ventilation disorders were the most common. Studies by Maasago M. Sepadi et al. identified increased health risks to miners due to chronic low levels of dust exposure and lack of use of RPE (respiratory protective equipment) (source). Not only is the health of workers who have direct contact with industries that generate dust affected, but also the health of people living near mines and quarries due to environmental pollution from dust. Samantha Iyaloo et al. studied the respiratory health of a community living near a gold mine waste dump and showed that residents living within 500 m of the mine had elevated adverse respiratory effects (source). Respiratory and ocular symptoms and objective measures of respiratory disease were higher among the more exposed groups of study participants; Maysaa Nemer et al. studied the lung function and respiratory health of residents near quarries in Palestine (source), exploring the negative health effects of environmental dust exposure in two communities near quarries in Palestine.

As an effective dust control technology, dust suppressant additives have been widely studied and applied. Therefore, several new dust suppressants have been developed. But even with their proven results, it is essential to effectively select and evaluate dust suppression performance based on the various dust prevention and control needs, environmental and safety requirements.

The evaluation indexes researched by Wu et al. for evaluating the performance of prepared dust suppressants include sedimentation performance, solution pH, wind erosion resistance, corrosion, toxicity, and economic benefits (source). Yanqiang LI proposed that the evaluation indexes of chemical dust suppressants should include corrosion, toxicity, environmental pollution, and cost performance. Thus, it is essential to select a dust control method taking into account the dust suppression technology’s performance, its economic benefit, and environmental safety.

Measuring toxicity:

Toxicity can be measured by the effect that a substance has on an organism, tissue, or cell. We know that individuals will respond differently to the same dose of a substance due to a number of factors, including gender, age, and body weight. Therefore, a population-level measure of toxicity is often used. The probability of an outcome for a population is then related to a particular individual in a population.

Lethal Dose (LD50):

LD50 is the amount of a material, given at one time, that causes the death of 50% (half) of a group of test animals. The LD50 is a way of measuring the short-term poisoning potential (acute toxicity) of a material.

Toxicologists can use many types of animals, but most often testing is done with rats and mice. It is usually expressed as the amount of chemical administered (e.g., milligrams) per 100 grams (for smaller animals) or per kilogram (for more significant test subjects) of the test animal’s body weight. The LD50 can be found for any route of entry or administration, but dermal (applied to the skin) and oral (administered orally) methods of administration are the most common (source).

Lethal Concentration (LC50):

LC values generally refer to the concentration of a chemical in the air, but in environmental studies, it can also mean the concentration of a chemical in water.

According to the Organization for Economic Cooperation and Development (OECD) Guidelines for Testing Chemicals, a traditional experiment involves groups of animals exposed to a concentration (or series of concentrations) for a set period of time (usually 4 hours). The animals are observed clinically for up to 14 days (source).

The concentration of the chemical in the air that kills 50% of the test animals during the observation period is the LC50 value. Other exposure durations (versus the traditional 4 hours) may apply depending on specific laws.

Where to Find Toxicity Information:

Before using any chemical, such as a dust suppressant, it is beneficial to know beforehand what your safe handling procedures are. What is the potential of the chemical to cause adverse biological effects in humans and animals? Is it a potential carcinogen, mutagen or teratogen? What is its LD50 or LC50 value? What is the chemical’s ability to bioaccumulate and persist in the environment? These data concerning the toxicology of a specific chemical are found in its Material Safety Data Sheet (MSDS). Also, information regarding the toxicology of a specific chemical or compound is found in government databases such as the National Toxicology Program (NTP).

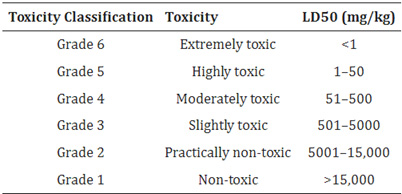

Table 1 Technical specification for chemical toxicity identification.

Material Safety Data Sheets:

A Material Safety Data Sheet (MSDS) is a document that contains information about potential hazards (health, fire, reactivity, and environment) and how to work safely with the chemical. It is an essential starting point for developing a complete health and safety program. It also contains information about the use, storage, handling, and emergency procedures, all related to the material’s hazards. The MSDS contains much more information about the material than the label. MSDSs are prepared by the supplier or manufacturer of the material. It is intended to tell you what the product’s hazards are, how to use the product safely, what to expect if the recommendations are not followed, what to do if accidents occur, how to recognize symptoms of overexposure, and what to do if incidents occur.

Types of Dust Suppressants

Dust suppressants include: water (fresh or salt); water absorbing salts such as sodium, magnesium, or calcium chloride salts or brines; organic non-petroleum adhesives such as lignosulfonate, animal fats, tall oil, and vegetable oil derivatives; organic petroleum products such as asphalt, organic solvents, oils and tars; electrochemical products such as enzymes, ionic solutions, and sulfonated oils; synthetic polymers such as polyvinyl acetate and vinyl acrylic emulsions; clay additives such as bentonite and montmorillonite; fibers, mulches, and geotextiles. Re-vegetation can also be used to control dust. The major dust suppressant categories are briefly described in the following section.

In addition to cost, the following factors should be considered when choosing a dust suppressant: its resistance to breakdown due to traffic and weather; its ability to stay on the road and not leach into the soil, groundwater, or surface water; its potential toxicity to humans during handling; its toxicity to organisms living in the environment (ecotoxicity), and its ability to bio-accumulate or bio-degrade.

Water:

Water is usually the most readily available dust suppressant. Both fresh and saltwater can be used to suppress dust. Repeated applications are required when using water as a dust suppressant due to evaporation. If salt water is used, there is a potential for chloride to accumulate which is potentially toxic to freshwater fish, plants and trees.

Water Absorbing Salts & Brines:

Calcium, magnesium and sodium chloride dry salts or brines control dust by absorbing moisture from the air causing the dust particles to bind together. These products are some of the mostly widely used dust suppressants. Calcium and magnesium chloride suppressants work at a lower relative humidity than sodium chloride salts and are more effective under dryer conditions. There would not be any expected human health concerns when handling these products, however, as with salt water there are potential impacts to freshwater fish and plants due to the accumulation, potential leaching and runoff of chloride. The experimental LD50 and LC50 values for various salt-based dust suppressant products range from the slightly toxic to practically non-toxic range (>500 ppm).

Organic Non-Petroleum Products:

Organic non-petroleum products include lignin sulfonate, tall (pine) oil, vegetable oil derivatives and molasses. Lignin sulfonate is derived from wood that has been treated with sulfuric acid to produce paper fiber and waste liquor which contains the lignin. Lignin sulfonate is water soluble so its effectiveness is limited in rainy climates. Tall (pine) oil is also a by-product of the paper industry and is recovered during the sulfate Kraft paper process. Tall oil contains rosin, oleic acid and linoleic acid and is also water-soluble, so it will break down after being exposed to rainwater. As with any type of oil, if large quantities are spilled into an adjacent waterway, these types of dust suppressants can cause harm to birds and mammals by coating their feathers or fur thus reducing their ability to keep warm. These types of dust suppressants also carry a high biological oxygen demand and can deplete the oxygen supply of an adjacent water body if leaching or spillage occurs, potentially resulting in fish kills.

Organic Petroleum Products:

Organic petroleum-based dust suppressants include liquid asphalt, modified asphalt emulsions, mineral oils and petroleum resins. These types of products are effective for controlling dust but may be the most toxic and are potentially carcinogenic. Asphalt and petroleum-based oils contain semi-volatile polyaromatic hydrocarbons (PAHs) and volatile organic compounds (VOCs), some of which are known human carcinogens. During application, the asphalt emulsion is commonly heated to allow for smooth application. The heated asphalt emulsion releases vapors which contain PAHs and VOCs that can be inhaled or absorbed through the skin of the people applying the product. The LD50 and LC50 values for some common petroleum-based dust palliatives range from moderately toxic (50-500 mg/kg) to slightly toxic (>500 mg/kg).

As with any chemical, the MSDS should be read before use to avoid personal injury during application. Once asphalt is stabilized it should not pose a risk to humans or wildlife. Liquid petroleum-based oils are not recommended for application near drinking water (groundwater or surface water) supplies due to potential contamination from leaching or stormwater runoff. Liquid petroleum-based oils should be used with extreme caution and kept away from waterways and wildlife areas.

Synthetic Polymer Emulsions:

Synthetic polymer emulsions include polyvinyl acetate and vinyl acrylic derivatives which bind or adhere to the dust particles. These types of dust suppressants increase the tensile strength (cohesiveness or bearing strength) of clay roads and only need to be applied once every few years. However, synthetic polymers tend to break down under moist and freezing conditions. The LD50 and LC50 values for some common synthetic polymer-based dust palliatives range from moderately toxic (50-500 mg/kg) to mildly toxic (> 500 mg/kg). Again, as with any chemical, the MSDS should be read before use to avoid personal injury during application.

Electrochemical Derivatives:

These types of dust suppressants include enzymes, acids, ammonium chloride, sulphonated oils and specialty products. These types of products generally work best with clay soils and act by reducing the water content of the soil thus increasing compaction. Some products are water soluble while others are highly acidic oxidizers and can react violently with metals. Minimal information is available concerning their ecotoxicity. The MSDS should be read before use to obtain toxicity information and to avoid personal injury during application.

Clay Additives:

Clay additives include natural clay materials such as bentonite and montmorillonite. These types of dust suppressants work best under dry conditions and act by agglomerating the fine dust particles and increasing the tensile strength of the soil. Wet conditions reduce their effectiveness. No toxic impact would be expected from using or applying these natural materials.

Is it possible to have an additive with high performance and no health, safety or environmental risk?

Yes, it is possible. This is how ABCDust developed its line of DMS® suppressors.

DMS® additives contain environmentally friendly, nonionic nanopolymers and copolymers modified to resist low temperatures. In addition, they contain APE-free surfactants with no added formaldehyde or flocculants.

Among its characteristics, we can emphasize:

- Nonionic;

- Hydrophobic;

- Improves load-bearing capacity (CBR);

- Reduces dust levels by 85-95%;

- Does not generate hydroplaning;

- Reduces braking distances, improving road safety;

- Improves road rolling resistance, reducing fuel consumption;

- Increases tire life;

- Non-toxic, non-corrosive and non-flammable;

- Water resistant, does not wash off;

- Resistant to salt, acid and alkaline water;

- Adjustable dosages to suit the type of use;

About ABCDust

ABCDust works hand in hand with mining companies worldwide to provide smart and sustainable dust control and soil stabilization solutions. Our dust control and soil stabilization services combine high-performance dust control & soil stabilization with georeferenced sensors and algorithms to provide an efficient treatment which is applied and optimized at the right place, at the right dose and time with the right equipment.

This translates in optimized performance and lower costs and minimizes mining operations’ environmental impact. ABCDust delivers its comprehensive solutions to the mining, forestry and municipalities worldwide at a very competitive price and complies with the highest HSEC standards.

Here are the benefits of our solutions for the mining industry:

- Reduce dust control costs and infrastructure maintenance costs;

- Stabilize and strengthen soil by mixing binding agents and sometimes extra structure into the soil;

- Control and monitor the Particulate Material (MP) to control dust emission from unpaved roads, crushers, stockpiles and other industrial process;

- Optimize the use of water and additives under the highest standards of safety, quality and environmental impact;

- Better logistics of your project with easier access and fewer vehicle journeys needed;

- Access your site no matter the weather with your strong and weather-protected soil;

- Lower permeability;

- Reduce up to 50% of road depth required to reach your bearing capacity;

- Push more workload with strong and compact surfaces at your site;

- Reduce road material loans by using our ionic soil stabilization products for clay soils;

- Prevent dust and other harmful material from coming off the roads and paths and into your site.