Friction and brake monitoring equipment

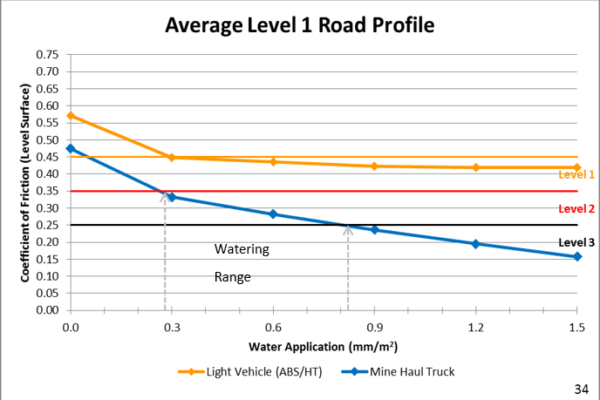

Many mining operations are tasked with finding the delicate balance between dust suppression and mine road safety. Dust suppression often results in conditions that are too slippery and can cause damage to staff and expensive operations equipment. Poor road friction and brake distance cause near 50% of accidents in mining operations. Over watering roads, rain, snow and cold weather reduce the road friction, increasing the risk of accidents.

ABC Dust uses VC4000DAQ, an advanced motion performance computers to correlate road friction to the proper application of dust suppression products. With our support, mine operators can maximize productivity with a haul road design process that improves haul truck productivity and safety.

Motion performance computer VC4000DAQ

Over 25 years of research and development have gone into the design of the VC4000DAQ making it the most innovative instrument for measuring tire to road friction and vehicle performance. Vericom’s reputation for excellence is truly displayed within the workings for the VC4000DAQ. Vericom is known world-wide for its accuracy in calculating vehicle speed and distance from acceleration and time.

ABCDust uses VC4000DAQ for its accuracy in calculating vehicle speed and distance from acceleration and time, ensuring brake distance and safe road friction conditions at different application rates in curves and slopes.

Vericom is the only performance computer in its price range that can accurately synchronize acceleration, speed, time and distance during vehicle braking which is partially due to Vericom’s RDP ™ (Run Duration Protocol). Now with OBDII CAN and built in 10Hz GPS interface the VC4000DAQ is its own working test module allowing the speed to be easily confirmed.

Technical details

- Built in 10Hz GPS

- Tri axis 2G to 6G accelerometer up to 1000Hz sample rate. Infinite storage time

- Digital leveling (self leveling) is done automatically

- Internal 2 axis angular rate gyro for measuring yaw and automatic pitch adjustment

- OBDll CAN input

- Simple calibration check procedures are displayed on the screen with step by step instructions

- Firmware (the software that runs the Vericom) is a menu select format and all upgrades can be made from the internet using the USB port

- Up to 16 sensors input

- Mapping

- PC communication by: USB, Bluetooth, SD card, 3 RS232 ports, streaming data

- Heavy duty single vacuum cup mounting system

- Built in 10Hz GPS

- Tri axis 2G to 6G accelerometer up to 1000Hz sample rate. Infinite storage time

- Digital leveling (self leveling) is done automatically

- Internal 2 axis angular rate gyro for measuring yaw and automatic pitch adjustment

- OBDll CAN input

- Simple calibration check procedures are displayed on the screen with step by step instructions

- Firmware (the software that runs the Vericom) is a menu select format and all upgrades can be made from the internet using the USB port

- Up to 16 sensors input

- Mapping

- PC communication by: USB, Bluetooth, SD card, 3 RS232 ports, streaming data

- Heavy duty single vacuum cup mounting system