Tailings Effective and durable Dust Suppression for Tailings Screens

Tailings are the third-largest source of fine mining dust. Their concentrations average between 0.7 and 1 mg/m2 of fine dust MP10, in moderate wind conditions (CIM 2020). High concentrations of fine dust MP10 and MP 2.5 affect respiratory and cardiovascular health and increase the spread of diseases such as VOCID-19 whose virion is 0.14 microns on average (SIMA, Setti, 2020). Heavy metals and toxic chemicals such as cyanide, arsenic, lead, silica, cadmium, zinc, and mercury, among others, can be found in tailings (Sernageomin 2015). Therefore, it is mandatory to control emissions from tailings dams because of their impact on nearby communities, flora, and fauna.

How to achieve effective and sustainable dust control?

To ensure effective and durable dust control in tailings dams, ABCDust performs the following stages:

1) Topographic and meteorological analysis of the area, surface-bearing capacity, tailing samples, and PM10-2.5 emissions and receiving areas.

2) Selection and testing of environmentally friendly additives, to determine effective and lasting rates and doses.

3) Selection of homogeneous and safe application methods to maximize results.

The professional development of these stages allows us to obtain results from 6 to 24 months, with levels of suppression of 90%, water savings of up to 95% in a safe and environmentally friendly way.

Dilution rate testing

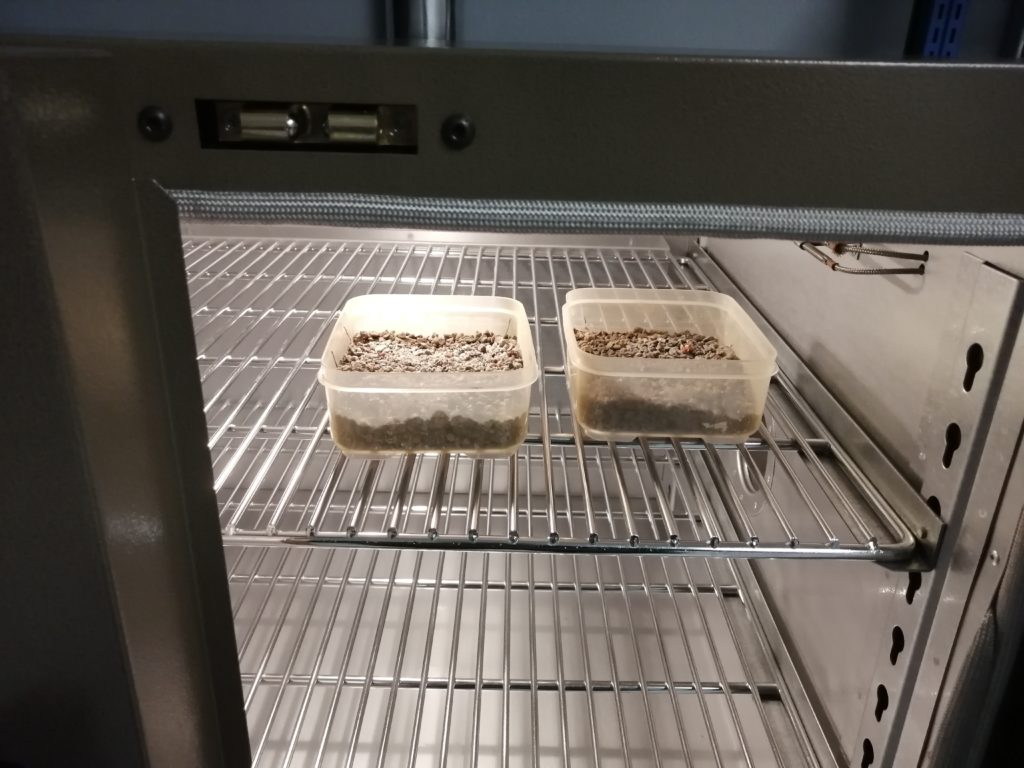

Drying Oven

Meteorological Analysis

Wind and UV Tunnel

Contact us for an evaluation!

Optimization of the application rates of biodegradable polymers DMS-TSF Dust Master System

Tailings Storage facilities (DMS-TSF) is the line of water-soluble biodegradable polymers for tailings dust control. Our polymers bind dust and maintain optimal surface moisture, reducing dust by 90% for extended periods, more effectively than water.

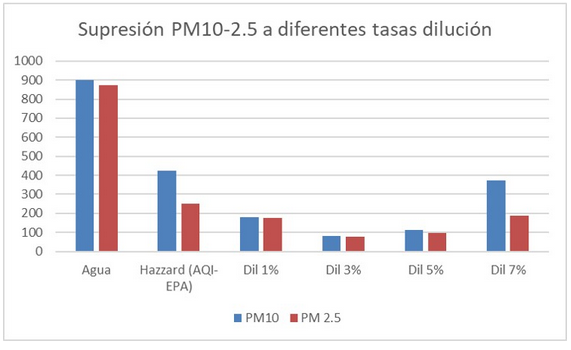

The rate and dose are calibrated with tailings samples, kiln drying, and wind tunnels. For tailings impoundments, ABCDust tests in its laboratories at the following rates:

Rates: 1 to 2 L/m2

Dilution: 2 to 7 V/V%

Depending on the type of material, climate, condition of the lock, and suppression goals, ABCDust chooses the additive and its dilution and application rate for an effective and long-lasting result. The suppressive efficiency at different dilution rates is analyzed below.

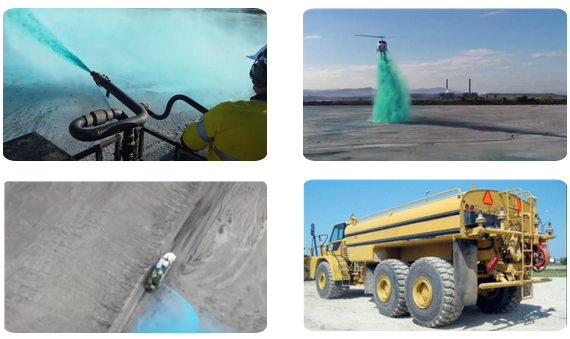

Homogeneous and safe application methods

According to the topography of the roadblock and its load capacity for the safe transit of people and vehicles, the use of different application methods is planned, such as

- Tank truck

- Long-range cannon

- Hoses

- Aerial irrigation

Effective long-term control!

Contact us!