Codelco Radomiro Tomic

In 2018, Codelco Radomiro Tomic (RT) conducted extensive testing of dust control and soil stabilization solutions for its mining ramps. Codelco RT was looking for competitive and safe solutions that would not interfere with the pit operation process, nor generate hydro-planning conditions and that would suppress 95% of the MP 10-2.5 dust.

Codelco RT, invited ABCDust with its DMS-DS solution, already validated at Codelco DMH to compare it with four other solutions from pre-qualified national and international suppliers. Each supplier tested their solution’s stopping distance and suppression efficiency capability on a 15% mining ramp over a period of one to two months.

DMS-DS is a nano-polymer-based dust control additive with an application protocol optimized for different soil types and traffic conditions. Applications of DMS-DS met targets for dust suppression efficiency of 95-98%, saved 80-90% water, and improved ramp stopping distances of 10-15% by 32-80%. In addition, ABCDust’s DMS-DS proved to be more effective and economical than salt and water chlorides by 40-60%, reducing accidents and maintenance costs.

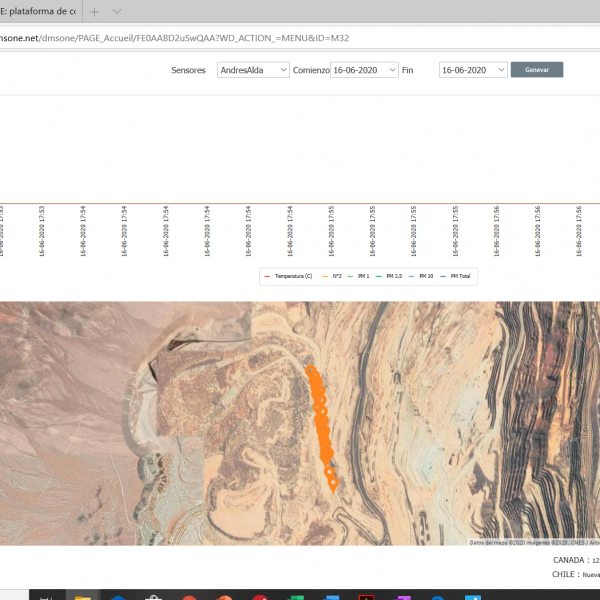

ABCDust’s excellent service and cost-effective solution was selected by Codelco Minister Hales and Codelco Radomiro Tomic as their current gold standard for road dust suppression. ABCDust is currently implementing its integrated mining dust management system, DMS-ONE, in Codelco Radomiro Tomic as a mechanism for continuous improvement and optimization of cost, safety and productivity of the fleet of trucks cisterns, water and additives throughout the pit.

Application pictures

Some pictures of the first application in Codelco Radomiro Tomic are detailled here.